Displacement ventilation (DV) is an advanced air distribution strategy that has gained significant traction in both commercial and industrial buildings for its superior indoor air quality (IAQ) and energy efficiency. Unlike traditional mixing ventilation, DV operates on a unique principle that prioritizes the delivery of clean air directly to occupied zones, ensuring optimal comfort and pollutant removal. Below is a comprehensive guide to understanding displacement ventilation, its key benefits, and critical design considerations.

1. What Is Displacement Ventilation?

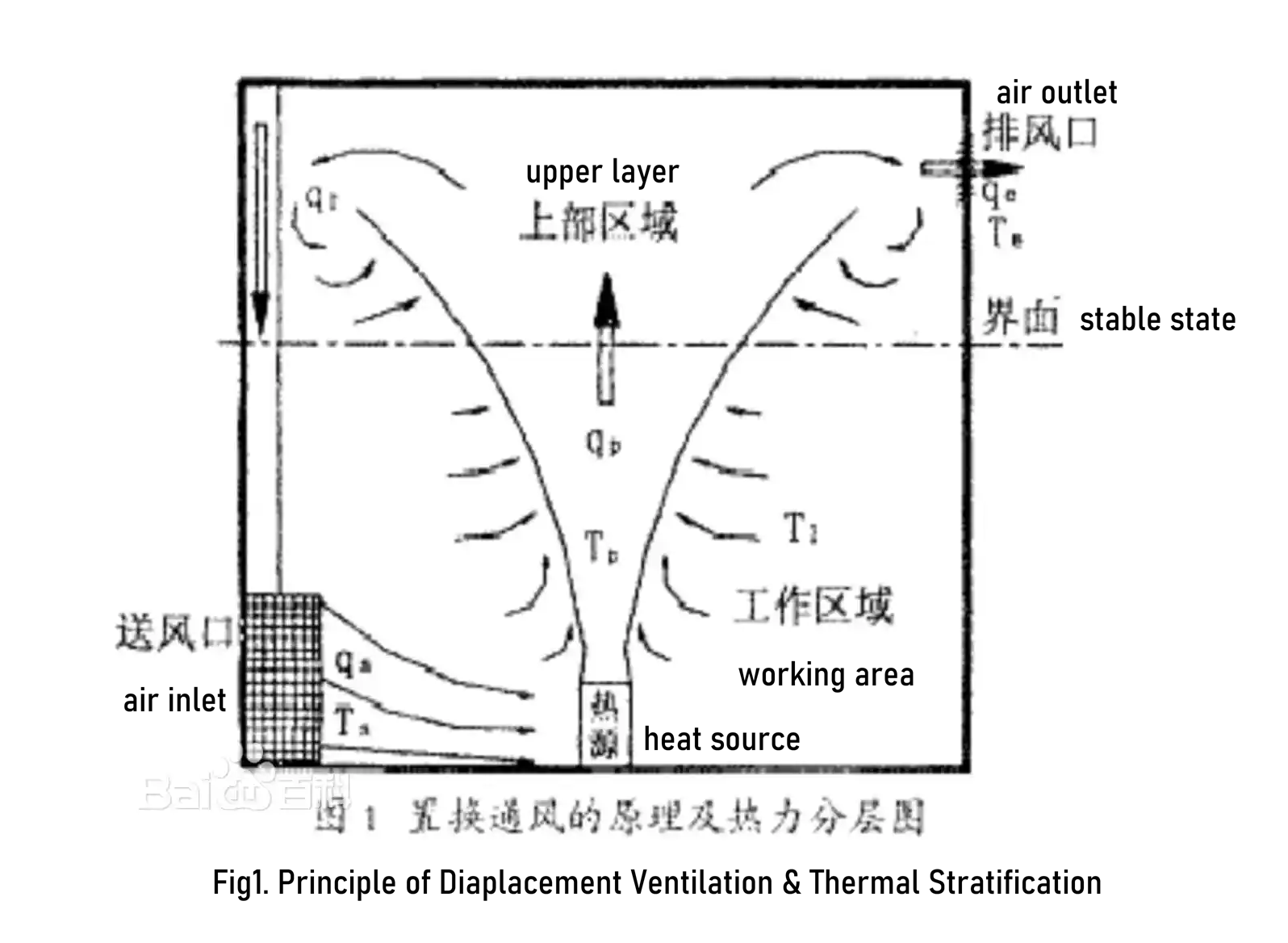

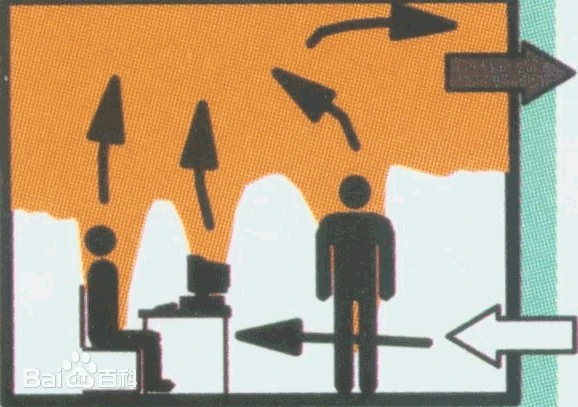

Displacement ventilation is a ventilation method that supplies conditioned (or unconditioned) air to the lower portion of an indoor occupied zone at low air velocity (typically 0.2-0.5 m/s), low turbulence, and minimal temperature difference relative to the indoor environment. The supplied air first spreads evenly across the floor surface, creating a “clean air lake” in the lower space. It then moves toward heat sources—such as occupants, machinery, or equipment—forming thermal plumes. These plumes rise upward, carrying residual heat, moisture, and pollutants, and eventually accumulate in the upper part of the room as a stagnant layer. Contaminants and excess heat are then exhausted from this upper stagnant zone, ensuring the occupied area remains supplied with fresh, clean air.

This buoyancy-driven airflow pattern is a hallmark of DV, distinguishing it from mixing ventilation which dilutes pollutants throughout the entire room volume. For more technical insights into airflow dynamics in DV systems, you can refer to resources from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), a leading authority on HVAC system design and standards.

2. Why Choose Displacement Ventilation?

The primary advantage of displacement ventilation lies in its targeted delivery of clean air to the areas where people actually reside—the occupied zone. In most buildings, the occupied zone (where occupants breathe and perform daily activities) accounts for only a fraction of the total room height: for civil buildings with a net height above 2.4 meters and industrial buildings with a floor height of 5.5 meters, the ratio of the breathing zone height to the total room height ranges from 0.27 to 0.46. By supplying fresh air directly to this zone, DV not only meets strict indoor hygiene standards but also enhances thermal comfort, as occupants are surrounded by cool, clean air rather than mixed, potentially polluted air.

2.1 Air Stratification: The Science Behind DV’s Efficiency

Displacement ventilation leverages thermal buoyancy to create vertical air stratification in the room. When DV operates stably, the indoor air is divided into two distinct zones: the lower unidirectional flow zone (occupied area) and the upper turbulent mixing zone (stagnant area). The lower zone features minimal airflow recirculation (near-displacement flow), ensuring air quality remains close to that of the supplied air. In contrast, the upper zone contains circulating air where hot, humid air and pollutants are trapped. The height of the stratification interface between these two zones is determined by three key factors: air supply volume, heat source characteristics (e.g., size, heat output), and the distribution of heat sources within the room.

A well-designed DV system positions this stratification interface above the occupied zone, guaranteeing that occupants breathe air with low pollutant concentrations and optimal temperature. For case studies on how DV improves IAQ in commercial buildings, visit the World Health Organization (WHO) Indoor Air Quality portal.

2.2 Key Advantages Over Conventional Mixing Ventilation

Compared to traditional mixing ventilation, displacement ventilation offers several notable benefits: it maintains superior air quality in the occupied zone by minimizing pollutant dilution, reduces energy consumption by focusing conditioning on the lower room volume, and enhances thermal comfort by avoiding drafty conditions associated with high-velocity air supply. The goal of DV design is to minimize airflow mixing in the occupied zone, ensuring the air quality in the working area is as close as possible to the supply air quality— a standard that mixing ventilation often struggles to meet.

3. Critical Design Considerations for Displacement Ventilation

While displacement ventilation offers numerous advantages, its successful implementation depends on careful design that adheres to specific conditions and regulations. Below are the key considerations to keep in mind:

3.1 Conditions for Adopting Displacement Ventilation

Displacement ventilation is most effective when the following conditions are met:

- The space contains heat sources (e.g., occupants, machinery) associated with pollutant emissions—DV relies on thermal plumes to remove pollutants, so heat sources are essential for proper airflow.

- Strict air quality requirements exist for the occupied zone (e.g., in offices, laboratories, or healthcare facilities where IAQ directly impacts occupant health and productivity).

- The room height is at least 2.4 meters—sufficient height is necessary to establish effective air stratification and accommodate the upper stagnant zone.

- Construction, craftsmanship, and decoration conditions permit DV installation, and the system is technically and economically feasible (e.g., compatible with building layout and budget constraints).

3.2 Design Regulations to Comply With

To ensure optimal performance and comfort, displacement ventilation systems must adhere to the following design regulations:

- The vertical temperature difference between the head and feet of occupants (head-foot temperature difference) must not exceed 3℃—this ensures thermal comfort and avoids discomfort from cold feet or overheated upper bodies.

- Airflow distribution in the occupied zone must be uniform—avoiding dead spots where air quality may deteriorate or drafty areas that cause discomfort.

- For industrial buildings, the air outlet velocity of built-in ventilation systems should not exceed 0.5 m/s—high velocities can disrupt the thermal plume and reduce stratification efficiency.

- For civil buildings (e.g., offices, residences), the air outlet velocity of built-in ventilation systems should not exceed 0.2 m/s—lower velocities are required to maintain comfort in spaces with prolonged occupant presence.

For detailed design standards, consult ASHRAE Standard 62.1-2022, which outlines ventilation requirements for acceptable indoor air quality, including specific guidelines for displacement ventilation systems.

Conclusion

Displacement ventilation is a highly efficient ventilation strategy that prioritizes occupant comfort and indoor air quality by leveraging thermal buoyancy and air stratification. When designed and implemented correctly—adhering to the necessary conditions and regulations—it outperforms conventional mixing ventilation in spaces with strict IAQ requirements and sufficient room height. By focusing on delivering clean air directly to the occupied zone, DV not only enhances occupant well-being but also contributes to energy savings, making it a valuable choice for modern building design.